Fly ash for example can be mixed with cement in ratios of fly ash to cement that range from 2080 to 8020 based on an equivalent sack weight that is where a sack of fly ash has the. For contiguous bored pile wall I normally used the following mixture to get compressive.

Blend Mix Proportions And Blend Slurry Properties Download Table

The bentonite-cement slurry specimens 8 cm in diam.

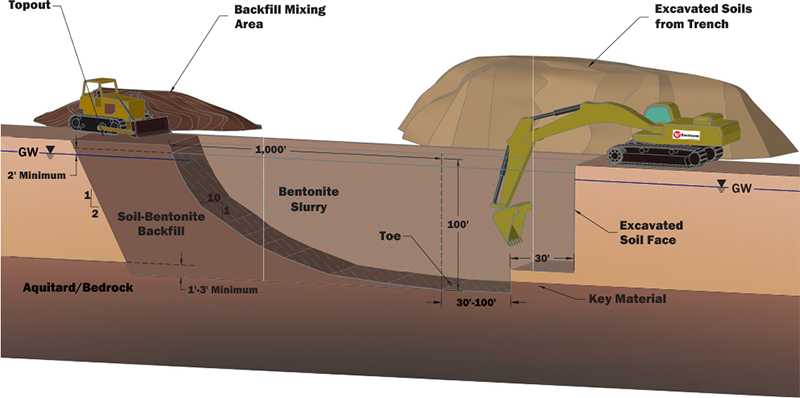

. Cement plus Bentonite Selected for reducing slurry density and increasing slurry volume Normal bentonite additions range from 1 to 12 percent by weight of cement bwoc For every 1 bentonite bwoc added the water content must be increased 065 gallons assumes dry blending Bentonite reduces resistance of cement to. 1 part of water 06-08 part of cement 04-02 part of bentonite and 0005-001 part of sodium carbonate. The penetrations are overlapped to construct a continuous barrier.

The cement-bentonite slurry preparation is prepared from the following raw materials in parts by mass. 1 part of water 06-08 part of cement 04-02 part of bentonite and 0005-001 part of sodium carbonate. The finished wall creates a thin groundwater barrier with low permeability.

When mixing on site its imperative to get the water volume with cement powder content right. Ad Sanft entgiften mit Bentonit. Accepted 9 May 2011 The aim of this study is to prepare a mix that can be used in impermeable fill as an alternative to clay.

Ad Sanft entgiften mit Bentonit. Designing the SCB backfill is a complex issue involving conflicting actions of the various materials involved. The preparation method comprises the following steps.

In general with bentonite cement. The paper presents the procedures used and the results obtained during an extensive laboratory testing program performed to select varying soil-bentonite slurry mix components for a soil-bentonite slurry cutoff wall constructed around an old landfill at. A slurry should be designed for its specific application with good properties to allow placement in a normal period.

This minimizes the slurry seepage out of the trench and groundwater seepage into the trench. Bentonite slurry is a combination of sodium bentonite and slurry. The ratio of the water to the sum of cement and bentonite is 11.

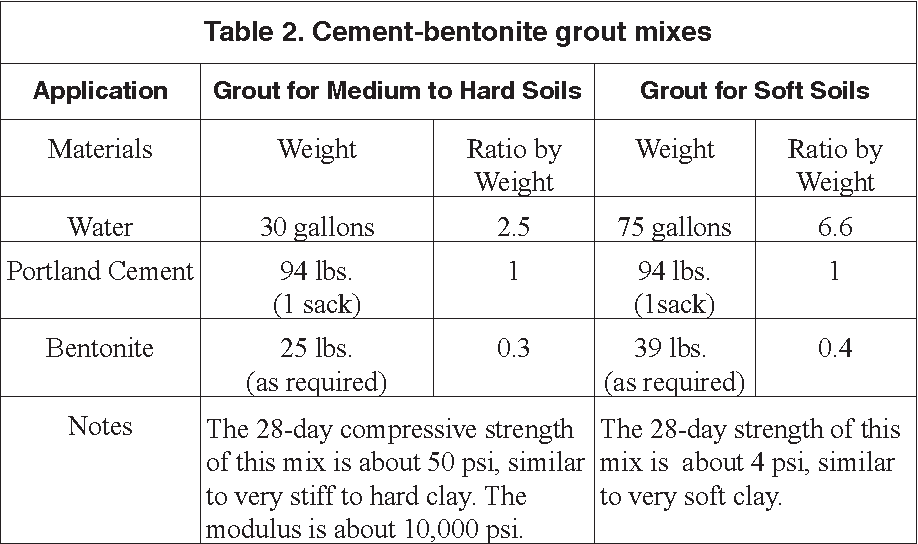

Tech grade or mud gel should not be substituted for cement-grade bentonite. CB Design Mix At least two weeks prior to construction the Contractor shall submit proportions and properties of the proposed CB design mix including cement bentonite additives and water proportions. The ideal cement slurry should.

The cement-bentonite slurry is injected during penetration and removal of the beam. Lignosulfonate is commonly used as a. The Use of Slag Cement in CB Seepage Cutoff Walls for Levees.

1100 Mountain View Ave. This minimizes the slurry seepage out of the trench and groundwater seepage into the trench. While the SCB wall provides additional strength permeability is one property that generally suffers in comparison to soil-bentonite slurry walls.

Typically SB backfill has a permeability in the range of 10-6 to 10-8 cmsec. In addition to these design standards designers shall integrate sound engineering judgment applicable national codes and design standards site-specific technical considerations and. Concerning the designing of bentonite-cement slurry composition.

If bentonite slurry is mixed first the water-cement ratio cannot be controlled because the addition of cement must stop when the slurry thickens to a consistency that is still pumpable. Barı ş Esener Department of Civil Engineering Faculty of Engineering Pamukkale University Denizli Turkey. Proportionally adding the water into a.

A normal permeability specification would be a maximum of 1 x 10 6 cmsec. Cement bentonite mix design Written By ways Thursday March 17 2022 Add Comment 32 13 1306. The procedure of designing the bentonite-cement slurry composition consists in determining of cement to benton-ite slurry ratio evaluation of bentonite content in the bentonite slurry and cement.

Have no measurable free water Provide adequate fluid-loss control Contain adequate retarder to help ensure proper placement Maintain a stable density to ensure hydrostatic control. The C-B slurry coats the sides of the trench with a thin slippery layer known as a filter cake. Mix Design Rules In order to keep field procedures simple the emphasis.

When water and cement are mixed first the water-cement ratio stays fixed and the strengthmodulus of the set grout is more predictable. This paper concentrates on the CB technique and particularly the permeability of various mix designs and the procedures for testing the mixes. A vibratory hammer is used to drive special steel beams to design depth along the wall alignment.

Pozzolanic materials are usually added in large volumes. The cement bentonite CB wall is a variation of the process in which cement is added to the slurry so that after the excavation process the slurry sets up without a separate backfilling operation. Usability of sand-bentonite-cement mixture in the construction of unpermeable layer Devrim Alkaya and A.

The C-B slurry is prepared by combining cement with a hydrated bentonite-water mixture just before discharge of the C-B slurry into the trench.

Geostrata May June July 2021 70 Years Of Soil Bentonite Slurry Walls So What S New

All You Need To Know About Bentonite In Cement Slurries Better Well Cementing For All

Barrier Walls Pollution Prevention Climate Policy Watcher

Design Proportions For Sccb Mix Design Program Download Scientific Diagram

Concrete Mix Design Used For Laboratory Tests Download Table

All You Need To Know About Bentonite In Cement Slurries Better Well Cementing For All

Sb Slurry Trench Cutoff Wall Schematic Lagrega Et Al 2010 Download Scientific Diagram

Pdf Cement Bentonite Grout Backfill For Borehole Instruments Semantic Scholar

0 comments

Post a Comment